In the world of chemical production, success hinges on precision. Every reaction, every pump, every valve needs to be meticulously orchestrated to generate desired outputs safely and efficiently. This is where EPCM services (Engineering, Procurement, and Construction Management) step in, acting as the conductor in the symphony of a chemical plant’s journey. And within this crucial framework, Front-End Engineering Design (FEED) plays the opening chords, setting the tone for the entire performance.

Decoding EPCM: A Partner for Progress

For chemical companies, navigating the complexities of project execution can be challenging. EPCM services address this by providing a comprehensive, integrated approach. From conceptualizing the initial idea to commissioning the operational plant, an EPCM partner takes ownership of every stage, handling:

Engineering: Process design, basic and detailed engineering, equipment selection, safety and environmental studies.

Procurement: Identifying, sourcing, and negotiating for materials and equipment at competitive prices.

Construction Management: Overseeing construction activities, managing contractors, and ensuring adherence to schedules and budgets.

But the effectiveness of EPCM relies heavily on the foundation laid during Front-End Engineering Design (FEED).

FEED: Planting the Seeds of Success

Think of FEED as the detailed blueprint for your chemical plant. It’s where the groundwork is laid, encompassing:

Process definition: Selecting the optimal production process, identifying potential hazards,and ensuring regulatory compliance.

Conceptual design: Developing preliminary layouts,sizing equipment, and estimating project costs.

Feasibility studies: Analyzing technical and economic viability, assessing risks, and identifying potential alternatives.

HAZOP (Hazard and Operability Study):Proactively identifying and mitigating potential operational hazards.

Key Considerations for Chemical Industry FEED

The intricate nature of chemical production demands specific considerations during FEED:

Safety first: Chemical plants inherently involve hazardous materials and processes. A robust FEED stage should prioritize safety by incorporating thorough risk assessments, process safeguards, and emergency response plans.

Process optimization: Choosing the most efficient and cost-effective production process while considering factors like raw material availability,energy consumption, and environmental impact.

Regulatory compliance: Navigating the complex web of chemical industry regulations is crucial. FEED should ensure the design adheres to all relevant safety, environmental, and operational standards.

Scalability and flexibility: Consider future expansion or product adjustments. Designs should be adaptable to cater to potential changes in market needs or production demands.

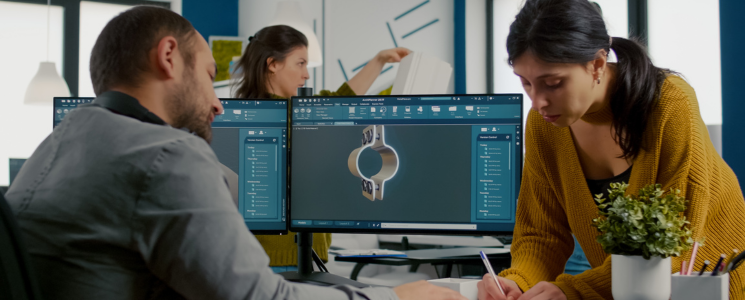

Technology integration: Leveraging advanced technologies like automation, digitalization, and real-time monitoring can enhance efficiency and safety. FEED should explore the potential integration of such solutions.

Quanta Process: Your EPCM Master

At Quanta Process, we believe in exceeding expectations. Our team of experienced engineers and project managers brings a wealth of knowledge and a commitment to excellence to every EPCM project. We understand the unique challenges of the chemical industry and tailor our FEED services to address your specific needs, ensuring safety, efficiency, and project success.

From navigating the intricacies of FEED to meticulously managing every stage of your project, Quanta Process is your trusted partner in transforming your chemical production vision into reality.

Contact Quanta Process today and let our EPCM expertise guide you towards a thriving chemical future.